A forerunner of responsible Namibian manufacturing, Plastic Packaging leverages forward-thinking packaging technology to help create a smarter, more sustainable future for the country. Nico Du Plessis, Managing Director, tells us more.

LEADING NAMIBIA’S CIRCULAR PACKAGING FUTURE

Namibia’s packaging industry offers an exciting but complex environment, particularly as sustainability and the circular economy take centre stage, resulting in a growing pressure to reduce waste, eliminate problematic plastics, and develop packaging that can reused, recycled, or composted.

For Plastic Packaging, this development is a powerful opportunity rather than a challenge. As Namibia’s only polymer and polyethylene terephthalate (PET) recycler, the company goes beyond conventional manufacturing by actively closing the loop, ensuring its products re-enter the market after use through robust recycling and reintegration processes.

“Our mission is to design packaging that fits within closed-loop systems, minimising environmental impact and extending the lifecycle of materials,” are the opening remarks of Nico Du Plessis, Managing Director.

However, Plastic Packaging also recognises that the path forwards is not without its obstacles. Evolving regulations, uneven recycling infrastructure, and cost pressures make systematic change difficult. Yet, these barriers also inspire innovation, as they drive the company to be more agile, foster cross-section collaboration, and invest in sustainable, long-term solutions.

“For us, packaging is no longer just about containment or protection – it’s about accountability and making sure that what we produce today doesn’t become tomorrow’s waste.

“The future lies in regenerative systems where packaging circulates continuously, creating value at every stage,” he asserts.

PRODUCTS, DIVISIONS, AND VISION

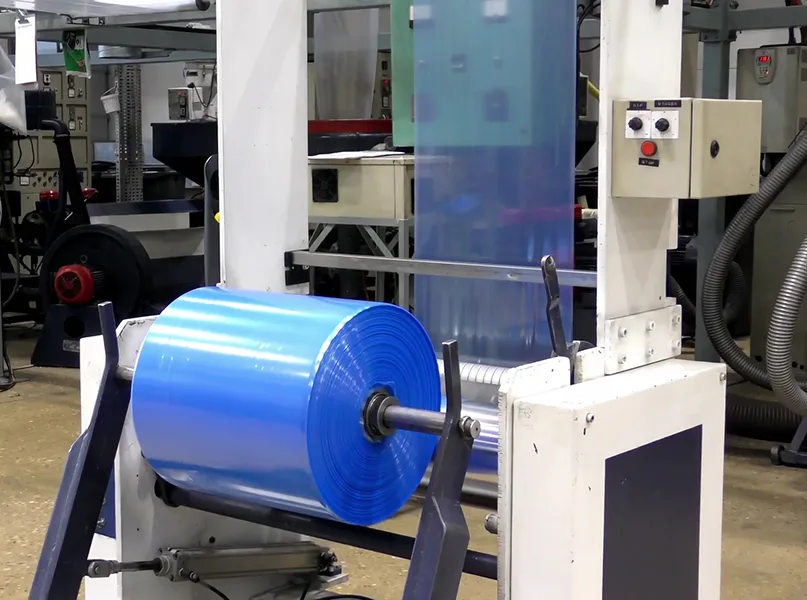

Plastic Packaging began in 1982 as a small blow moulding and extrusion operation using repurposed equipment from a local dairy farm.

In 2001, the company became fully independent and proudly Namibian-owned. Since then, Plastic Packaging has steadily expanded its footprint across the country and into South Africa (SA), operating 12 branches and four manufacturing facilities, whilst its main production plant in Windhoek, Namibia’s capital, serves as the company’s operational hub.

Over the decades, Plastic Packaging has evolved to become one of the nation’s leading manufacturers and a trusted provider of complete and flexible packaging solutions, serving a wide range of sectors with both locally manufactured and internationally sourced products.

Offering both standard products and custom designs, the company supports the agriculture, retail, food processing, and manufacturing industries, whilst its food safety-certified facility in Windhoek produces high-quality food-grade packaging according to European Union (EU) specifications and tailored to clients’ needs.

“Our approach combines quality, innovation, and responsiveness to deliver across the entire supply chain,” Du Plessis highlights.

Sustainability also lies at the heart of Plastic Packaging. Established in 2008, the company’s Recycling Division in Okahandja recycles high-density polyethylene (HDPE) and low-density polyethylene (LDPE) plastics, as well as PET since 2024.

Additionally, in Okahandja, the company’s subsidiary Namibia Plastic Converters (NPC) manufactures pipe solutions for water mains, irrigation, and sewer and drain systems using recycled materials, further extending the value chain.

Last year, the subsidiary launched its state-of-the-art PET recycling plant, making Plastic Packaging Namibia’s only polymer and PET recycler. Utilising a closed-loop approach, the plant turns waste into valuable new resources, thus promoting a thriving circular economy.

As founding members of the Namibian Manufacturers Association (NMA) and the Recycle Namibia Forum (RNF), Plastic Packaging is also committed to advancing both industrial development and environmental responsibility.

“With over four decades of experience, strong local roots, and a clear focus on innovation and sustainability, Plastic Packaging continues to lead the way in delivering smarter, greener packaging solutions across Southern Africa,” Du Plessis prides.

PROUDLY NAMIBIAN, LOCALLY ROOTED

Employing more than 500 staff across the company, Plastic Packaging remains proudly Nambian-owned, granting it a competitive edge.

“We understand the local context – its challenges, opportunities, and customers’ needs – allowing us to respond with agility and relevance. Our decisions are made locally, informed by experience, and tailored to serve the Namibian market effectively,” Du Plessis emphasises.

Unlike other manufacturers driven by external shareholders, Plastic Packaging has a long-term focus rooted in national development – reinvesting in local operations, building skills within its communities, and contributing meaningfully to the economy.

This, in turn, strengthens the company’s relationships with clients, suppliers, and partners who value reliability, accountability, and shared growth.

A further differentiator is Plastic Packaging’s integrated approach; as Namibia’s only recycler of polymer and PET plastics, the company has end-to-end control in the packaging lifecycle, driving the country’s circular economy goals.

“This combination of local ownership, industry leadership, and environmental responsibility positions Plastic Packaging as more than a supplier – we’re a long-term partner dedicated to building a smarter, more sustainable future for Namibia and the broader region,” Du Plessis insights.

Plastic Packaging’s commitments to nationwide growth go beyond manufacturing, as it also continuously invests in its workforce through training, skills development, and study support to build internal capacity and promote long-term growth, making its people a key priority.

Sponsorship of staff sports and wellness initiatives also plays a key role in strengthening team culture.

“These investments – both in infrastructure and our people – reflect our long-term vision to lead in responsible packaging, deliver value locally and abroad, and contribute meaningfully to Namibia’s and SA’s industrial and social development.”

As such, Plastic Packaging has a long-term commitment not only to sustainable products but building local skills, creating jobs, and supporting economic growth.

STEADFAST SUSTAINABILITY STRATEGY

One of Plastic Packaging’s most impactful projects to date is the launch of its PET recycling facility in partnership with Coca-Cola Beverages Africa (CCBA).

With a capacity of 4,600 tonnes per annun, the plant enables Plastic Packaging to recover pre- and post-industrial and consumer HDPE, LDPE, and PET waste that would otherwise end up in landfills.

This achievement reinforces the company’s commitment to sustainability and strengthens its role as Namibia’s only polymer recycler.

The project supports circular economy goals by conserving resources, reducing carbon emissions, and creating local employment. It also enhances Plastic Packaging’s ability to offer truly closed-loop solutions to clients throughout Southern Africa.

“Across the company, we prioritise responsible sourcing, energy efficiency, and waste minimisation, actively supporting Namibia’s shift towards a circular economy.”

Plastic Packaging further works towards these goals by ensuring that all its manufacturing facilities are equipped with rooftop solar systems to reduce both grid dependency and carbon emissions.

The company’s main production plant in Windhoek, for instance, operates on a 527-kilowatt (kW) solar installation, whilst its recycling facilities are powered by a 614kW system.

“These investments not only lower our environmental footprint but also demonstrate our long-term commitment to clean, renewable energy in both production and recycling,” Du Plessis expands.

LOCAL IMPACT, LONG-TERM VALUE

Alongside the abundance of eco-friendly benefits afforded by Plastic Packaging’s plants, the company also notably leads the incorporation of Namibian recycled plastic into everyday products.

“We are proud to be the only company in Namibia that manufactures shopping bags and refuse bags along with more than 80 other products using locally recycled waste. This approach reduces dependence on virgin materials and strengthens the national recycling ecosystem,” Du Plessis highlights.

Its eco-conscious products include its STAR refuse bags, which are produced entirely from recycled materials, whilst the PET waste collected at the company’s facilities is transformed into practical items such as grape punnets, smoothie cups, and clamshell packaging.

These efforts not only decrease landfill waste but also generate employment and promote a culture of environmental responsibility throughout Namibia.

Building infrastructure that allows people to earn an income from collected waste is essential to the company, not only environmentally but socially.

“In the absence of a mechanical plastic recycler in Namibia, such waste would otherwise end up in landfills, holding no economic value.

“By establishing recycling plants, we help convert waste into opportunity, enabling businesses to thrive by transforming waste into revenue. Our role in assigning value to waste is a cornerstone of creating a sustainable, inclusive model where all stakeholders benefit.”

Plastic Packaging additionally takes part in cleanup campaigns across the country and actively supports the RNF. Through this partnership, the company helps advance Namibia’s recycling sector and improve awareness around the importance of national waste management practices.

As such, Plastic Packaging’s involvement in community-based projects is a key part of its mission to make a positive impact.

DELIVERING A SMARTER FUTURE

In the year ahead, Plastic Packaging’s focus remains on scaling impact through sustainability, innovation, and workforce development.

More specifically, the company’s top priorities are to increase the volume of post-consumer waste processed at its PET and polymer recycling facilities and strengthen the closed-loop system to reduce reliance on landfills.

Plastic Packaging additionally plans to expand its product offerings to incorporate more recycled content, particularly in sectors such as agriculture and construction where sustainable initiatives are in demand.

“Investing in automation and production efficiency across our manufacturing facilities will help us enhance product quality and competitiveness,” Du Plessis surmises.

The company’s workforce also remains at the heart of Plastic Packaging’s growth strategy.

“We’re committed to ongoing employee development through skills training, study support, and mentorship. We will also expand our wellness initiatives, including staff sports sponsorships and engagement programmes, to foster a strong and motivated workforce,” he surmises.

Furthermore, Plastic Packaging aims to deepen its partnerships with government, industry, and communities to align with national sustainability goals and broaden its positive impact.

“Our overarching goal is to continue leading as a responsible Namibian manufacturer – delivering smarter packaging solutions whilst creating value for the environment, our clients, and the communities we serve across Southern Africa,” Du Plessis concludes.