We revisit Sulzer South Africa and Managing Director, Henry Craukamp, who enlightens us about the company’s ability to maintain certainty through its partnerships with customers in an uncertain business environment.

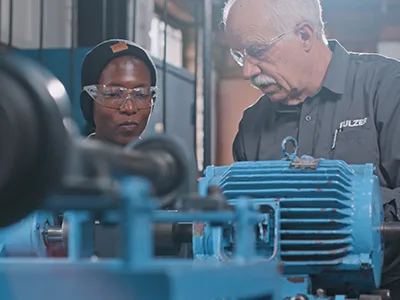

POWERING PARTNERSHIPS BEYOND PUMPS

Established in 1922, Sulzer South Africa (Sulzer) quickly grew to become a highly established original equipment manufacturer (OEM) of pumps across the country.

Since last featuring the company in 2023, Sulzer has continued to deepen its focus on developing maintenance and repair solutions around its customers’ rotating equipment needs, something which Managing Director, Henry Craukamp, has been passionate about since his appointment to the role three years ago.

“By focusing on our customers’ needs, we started employing a preventative technology that transitioned our service orientation from reactive to proactive,” he opens.

Indeed, Sulzer supports customers across the entirety of their operations by providing cutting-edge maintenance and repair solutions for pumps, turbines, compressors, motors, generators, and high-speed gearboxes.

“The next phase of our support will target predictability using digital tools powered by machine learning (ML) technology. I believe this will enable us to unlock further potential in partnership with our customers,” Craukamp adds.

An additional key initiative for the company is the implementation of a track and trace platform that creates a digital footprint for every asset made, supporting customers with effective lifecycle management and leveraging real-time data to benchmark asset performance.

Sulzer is therefore able to maintain a complete record of its customers’ equipment from the moment it is added to the main database. The data can subsequently be accessed instantly by the field services team by simply scanning a QR code, enabling faster and more informed responses and decisions.

This capability significantly reduces downtime, minimising costs for customers and safeguarding their critical infrastructure.

“Real-time data is essential for digital tools to be effective, but this may not be feasible for some high-security industrial customers who could be at risk of malicious activity. In these cases, we deploy secure, on-site monitoring tools that operate independently of the customer’s control system,” he highlights.

This allows Sulzer to safely gather the data needed for its artificial intelligence (AI) platform to assess equipment risk accurately.

“Since every customer is at a different stage in their digital transformation, it’s vital that we work closely with them to offer tailored recommendations that suit their unique needs.”

“Since every customer is at a different stage in their digital transformation, it’s vital that we work closely with them to offer tailored recommendations that suit their unique needs”

Henry Craukamp, Managing Director, Sulzer South Africa

END-TO-END SUPPORT

Sulzer serves a broad range of industries across South Africa (SA), such as oil and gas, chemical, water infrastructure, wastewater, power generation, and mining, with its Flow and Services divisions.

The former specialises in delivering engineered solutions, which includes the supply of pumps, mixers, compressors, and other fluid handling equipment.

The Services division, meanwhile, deploys a lifecycle approach to maximise equipment uptime, efficiency, and longevity for both Sulzer and its equipment. This is achieved through the company’s comprehensive maintenance, repair, and upgrade solutions for rotating equipment.

“We also operate several specialised facilities across SA to support our customers with localised expertise and service,” Craukamp states.

In Johannesburg, for instance, Sulzer has its Advanced Manufacturing Centre (AMC), a dedicated Service Centre for pumps, and a separate facility for electromechanical equipment.

The AMC in particular utilises state-of-the-art machinery and tooling equipment combined with rigorous quality control processes to produce world-class parts.

Its Service Centre meanwhile, is able to repair, overhaul, and improve all types of rotating machinery, allowing the company to support the complete drivetrain system, whilst the electromechanical centre is uniquely equipped for the refurbishment of high-speed, complex gearboxes.

“These bespoke facilities ensure Sulzer exceeds market requirements amidst the country’s skills shortage,” Craukamp points out.

Elsewhere in Durban, the company has another new Service Centre dedicated to the pulp and paper and industrial water sectors, whilst an additional facility in Welkom focuses on supporting gold mining operations, energy recovery systems, and large vertical turbine services.

“With sales offices in both Johannesburg and Durban, alongside our extensive footprint across the country, we effectively serve customers throughout SA and the broader sub-Saharan Africa region.”

ENACTING CHANGE

Operating nationwide, Sulzer strives to be a good corporate citizen and consistently makes a positive difference across SA.

For example, the company is proud to be a Level 2 Broad-Based Black Economic Empowerment (B-BBEE) contributor, reflecting its ongoing commitment to transformation, empowerment, and inclusive economic growth.

“This status not only strengthens our partnerships with customers and suppliers but also demonstrates our active role in supporting SA’s socioeconomic development goals,” Craukamp asserts.

Sulzer is likewise dedicated to developing critical skillsets that will benefit the country as a whole.

“In a recent conversation, someone asked me why it’s so difficult to fill positions when unemployment is so high. The reality is a persistent skills gap, and it is therefore our responsibility to engage with people across society to help close that gap,” he impassions.

This approach includes actively participating in industry initiatives and partnerships that promote skills development, as the company believes that it can have a far greater impact by collaborating across companies and communities rather than operating on its own.

In a similar vein, Sulzer also prioritises creating teams comprised of the local workforce, as evidenced by its regional engineering team that has been integrated into the company’s global R&D network.

As a result, Sulzer has access to a vast pool of international expertise, ensuring its capabilities remain world-class.

A prime example is its Hydro-Mining division, which specialises in underground drilling equipment for mining applications. Notably, all R&D for this division is conducted locally in SA.

“Our continued investment in R&D has positioned us as a leader in several areas. For example, we are the only company offering both air drills for higher-level mining operations and pneumatic drills capable of functioning at depths greater than 1,000 metres – an essential capability given the depth of many South African mines,” Craukamp remarks.

Beyond technical innovation, Sulzer’s R&D efforts have far-reaching and meaningful social impacts. For instance, its team recently developed a drill that is six kilogrammes lighter than the industry standard, reducing physical strain on users.

“This advancement not only promotes better health outcomes but also opens the door to greater gender inclusivity in mining roles – an industry traditionally dominated by men.”

“We live by our principles every day, and as a result, we’ve remained a reliable, long-term partner to our customers. In a world of constant change, Sulzer offers something incredibly rare – stability”

Henry Craukamp, Managing Director, Sulzer South Africa

CENTENARY CELEBRATION

Sulzer is proud to have recently celebrated its 100th anniversary, having grown alongside SA’s key sectors as an integral pillar in the development of infrastructure, energy, mining, water, and industry.

From humble beginnings to becoming a trusted leader in engineered solutions and services, the company’s journey has been marked by resilience, transformation, and a meaningful contribution.

“Our centenary is more than a milestone – it’s a testament to the enduring strength of our brand, role as a responsible corporate citizen, and the positive impact we’ve made in local communities.

“It reflects a century of commitment to innovation, service excellence, and partnership across the industries we proudly serve,” Craukamp insights.

This achievement also speaks volumes about the people behind the company’s success. Indeed, with an average employee tenure exceeding 15 years, Sulzer’s team loyalty and dedication are well above the industry norm, underscoring the strength of its culture and shared purpose.

“We live by our principles every day, and as a result, we’ve remained a reliable, long-term partner to our customers. In a world of constant change, Sulzer offers something incredibly rare – stability,” he prides.

Going forwards, the company’s focus remains firmly on three core priorities; namely customer centricity – truly understanding what keeps its customers up at night; an outcome-based mindset – ensuring its solutions are directly aligned with its customers’ needs; and its people – engaging a highly-skilled and committed team.

This will allow Sulzer to continue delivering cutting-edge technologies, developing local talent, and contributing to the sustainable progress of SA.

“Our approach is brought to life by continuously maintaining our principles – seize opportunities, own it, team up, and create value,” Craukamp concludes.

Editor’s note: Many of the business leaders featured by Africa Outlook continue sharing their insights on LinkedIn. For executives across Africa seeking to strengthen their online presence, visit LinkedIn profile optimization.