As Petromar celebrates its 40th anniversary this year, Frederic Heintz, General Manager, tells us more about the company’s pioneering fabrication and maintenance activities that ensure its continued success.

40 YEARS OF EXCELLENCE IN FABRICATION AND MAINTENANCE

Angola is internationally renowned for its plentiful natural resources, including specialist metals, minerals, and oil reserves found both underground and on the seafloor.

Looking at the nation’s oil and gas activities in particular, Angola has advanced to become the second-largest oil producer in sub-Saharan Africa and a key member of the Organisation of the Petroleum Exporting Countries (OPEC).

Angola’s oil and gas industry represents tenacity and versatility in the face of historical challenges, namely the impacts of a civil war that took place between 1975 and 2002 that it is still navigating.

As such, Angola’s oil and gas developments over the last 20 years represent a positive evolution, as the sector has enabled measurable socioeconomic impacts across the country.

For example, the 17.9 million cubic feet of natural gas production nationwide makes the industry the largest contributor to Angola’s GDP and has solidified the country’s economic growth.

As part of its progression, the oil and gas industry is pivoting more towards environmental considerations in an increasingly sustainable world.

Consequently, companies operating in the sector are adopting strategies to reduce their greenhouse gas (GHG) contributions, including using less polluting technologies and prioritising the protection of local wildlife.

Angola’s subsea sector, in particular, is a key pillar of the West African oil and gas industry, with an abundance of deep sea resources that are extracted by both global and domestic businesses.

Standing at the head of the Angolan subsea sector and floating, production, storage, and offloading (FPSO) activities is Petromar, who has pioneered forward-thinking solutions across the industry since 1984.

AN INNOVATIVE AND DETERMINED HISTORY

Petromar was established in Ambriz, a village and municipality in the Bengo Province, as a joint venture between Sonangol, the state-owned Angolan operator, and originally Bouygues Offshore, later acquired by Saipem, an Italian engineering and construction services organisation.

The company was notably the first fabrication yard of its kind in Angola to partner with Sonangol and ELF, a TotalEnergies brand, making it a pioneer in its field.

Additionally, despite the rudimentary use of technology at the time, Petromar reached new heights in fabrication activities, cementing its place as an industry leader at an early stage in its journey.

The company initially focused on the fabrication of platforms for the shallow waters in Blocks 0 and 3 of Sonangol’s oil development. However, in 1997, due to the Angolan Civil War, Petromar could no longer conduct its operations in Ambriz, forcing it to transfer its assets to Soyo, where the business could continue to attend to oil and gas market demands.

During this time, Petromar gained considerable competence in subsea development projects, including the Rosa oil field project for TotalEnergies and the Kizomba Satellites project for ExxonMobil, amongst more.

In a major turning point, the company returned to its original yard in Ambriz in 2010 and, as a result, was able to operate the two yards simultaneously for the next five years. This dual activity also meant Petromar could effectively navigate the oil and gas market, which was experiencing a major resurgence at the time.

Following these high demands and the crisis in the sector, Petromar rethought its strategy and subsequently decided to concentrate its efforts on fabrication activities in Ambriz, closing its yard in Soyo.

An additional milestone was achieved when Cabinda Gulf Oil Company (CABGOC) moved all its contractors out from its Malongo terminal in Cabinda, enabling Petromar to establish a second six-hectare (ha) yard in Malembo, thus helping to support the company’s fabrication maintenance activities with CABGOC.

Evidently, Petromar’s journey for the past four decades has been one of innovation and determination.

“We have been resilient in overcoming industry crises, including market booms, crashes, and reductions,” introduces General Manager, Frederic Heintz.

This has been achieved by the strategic investment in its assets over the last four decades, demonstrating an outstanding flexibility in adapting to sector evolution and past crises.

Such perseverance, durability, and adaptability in an ever-changing industry has enabled Petromar to become the second-largest active fabrication yard in Angola.

“Our vast experience in subsea structures and platforms demonstrates our capacity to embrace new challenges and engage in bigger projects that are more demanding and complex,” he adds.

FABRICATION AND MAINTENANCE EXPERTS

The Angolan oil and gas industry is reputed for its stringent safety, quality, and engineering standards.

Petromar endeavours to meet these standards across its two main business activities – the fabrication of subsea structures and the maintenance of oil and gas infrastructure.

Throughout its extensive history in the sector, the company has grown to become a leader in the former thanks to its outstanding assets and Angolan resources.

Indeed, Petromar fabricates subsea structures including pipeline end terminals (PLETs), jumpers, manifolds, mudmats, and more. Additionally, the company produces topside, module, and jacket platforms.

“Usually, those projects are developed together with our main shareholder, Saipem, who performs the engineering, procurement, and installation offshore, whilst Petromar concentrates on the fabrication of structures, currently performed in our Ambriz yard,” informs Heintz.

Meanwhile, Petromar’s maintenance of offshore and onshore oil and gas infrastructures include the Block 3 platform for Sonangol, in the last 35 years.

Elsewhere, the company maintains Blocks 18 and 31 with two FPSOs for Azule Energy, whilst also working with CABGOC to execute fabrication maintenance activities for Blocks 0 and 14, maintaining their structure and piping.

Those operations are also supported by a logistics and industrial base in the Angolan capital of Luanda, next to the company’s headquarters, where it performs smaller fabrication jobs and preparations for offshore activities.

Across four decades of operation, Petromar has strived to gain the competence and trust of its clients.

“With the support of shareholders, there is no doubt that the execution of our projects will maximise local content and fabrication services in Angola,” explains Heintz.

As such, the company’s long-term success is aided by the support of its stakeholders, which include the local authorities, financial and institutional partners, suppliers, and subcontractors that help Petromar achieve high standards in timely delivery, with the reactivity of mobilisation equipment and resources.

“Our vast experience in subsea structures and platforms demonstrates our capacity to embrace new challenges and engage in bigger projects that are more demanding and complex”

Frederic Heintz, General Manager, Petromar

LANDMARK MANUFACTURING

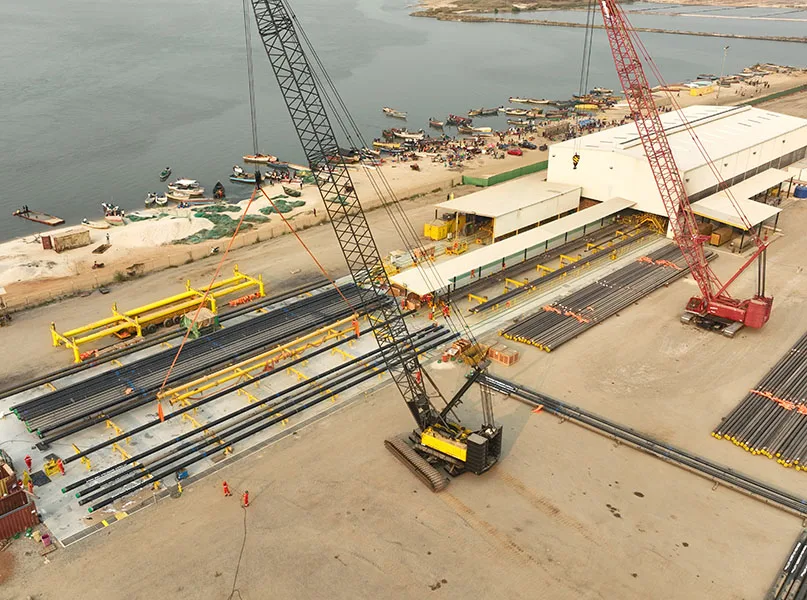

Between August 2023-24, Petromar continued to develop two ongoing manufacturing projects for Azule Energy at its Ambriz yard.

Firstly, the company manufactured 20 PLETs to accompany 10 mudmats already installed at sea in January 2024 as part of the Agogo Integrated West Hub project, which is in the final phase of loadout testing.

Petromar has also manufactured 297 pipe-in-pipe quadruple joints for the pipelines used in the flowlines at the bottom of the sea, which aim to reduce installation times offshore.

“We are the only company in the country to realise this technology, as the entirety of the pipeline, including the outer pipe, inner pipe, and the insertion of the latter into the former pipe, is all manufactured on one production line in a specially-built workshop,” Heintz highlights.

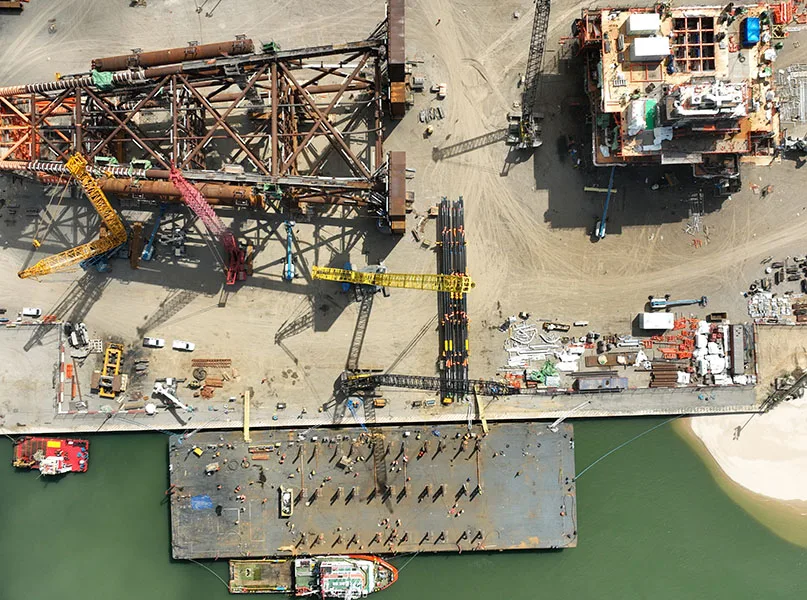

Petromar’s second project is to manufacture the Quiluma platform for the New Gas Consortium (NGC), Angola’s first non-associated gas project operated by Azule Energy.

The structure comprises a 2,200-tonne (t) jacket and 2,500-deck with four levels, containing hundreds of kilometres of cable.

“It represents a milestone for the industry, led by Azule Energy and their partners, for which Petromar is enthusiastic about participating in its achievement,” he expands.

Both structures are yet to be completed, but the company has witnessed visible progress across the two operations.

In order to face those additional challenges expected by clients, in 2022 the company expanded its surface area by 7ha, reaching a total of 33ha. Furthermore, Petromar became the largest employer in the Bengo province with approximately 1,500 direct workers.

Finally, the company has also been awarded an additional subsea development contract by Azule Energy in the Ndungu field, working on Block 15/06.

“This has granted continuity in the workload of the yard and brought a new work front for next year, with multiple structures to fabricate.”