Arenel : Moving Forward Locally and Regionally

Arenel has achieved local and regional growth throughout its decades of continuous operational improvement in the manufacture of quality sweets and biscuits for Zimbabweans and its key export markets.

Vivo Energy and Innscor Bring Quick Service Restaurants to Shell Customers

Vivo Energy has announced an extension to its existing partnership with Innscor to add quick service restaurants at a number of its service stations in Namibia and Botswana.

Lodestone Brands : Taking Businesses to the Next Level

Lodestone Brands is looking to expand its acquisition portfolio across Africa, building on an initial six years of success in the FMCG market.

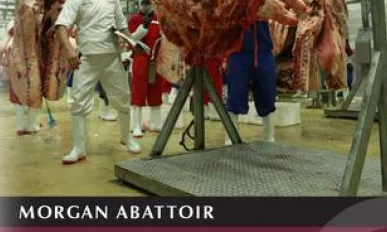

Morgan Abattoir : Livestock Innovation

By keeping abreast of industry and economic changes, Morgan Abattoir looks to grow its business in a sustainable manner.

Omnicane : Remaining Sustainable

Investments made in value added services, including electricity generation for self-sustainable operations, has allowed Omnicane to try its hand in a whole host of associated industries.

Moldon : Taking the Brand Forward

As first-hand experts in the food and drink industry, Moldon continues to actively involve itself in the market in order to gain brand exposure and build a reputation for quality and efficiency.

Kenblest Group : The Right Ingredients for Success

Business has remained steady for Kenblest over the past year and the increased capacities from replacing its ovens and machinery are sure to encourage future growth in the Kenyan market.

Coca-Cola Sabco Mozambique : Becoming World-Class Together

With an estimated consumer base of 24 million people in Mozambique, Coca-Cola Sabco has been increasing production capabilities nationwide by stabilising its distribution network and investing in state-of-the-art equipment.

Africa’s Big Seven : Following Urban Africans Supermarket Trends

Africa's Big Seven (AB7) is the biggest food and beverage trade exhibition on the continent, creating opportunities for a wide selection of companies.

Unilever Food Solutions : Catering for Changing Tastes

Backed by a team of dedicated staff, Unilever Food Solutions aim to deliver high quality products and service excellence to remain a market leader in the food industry.

Coast Millers : Bigger Leads to Better

One year on and with a vast increase in capacity in place, Coast Millers has turned its attentions towards adding value to its products.

Lusitania Food Products : Positive Thinking, Positive Results

Lusitania Food Products continues to increase and diversify its range of products to complement its equally flexible supply chain management strategy.