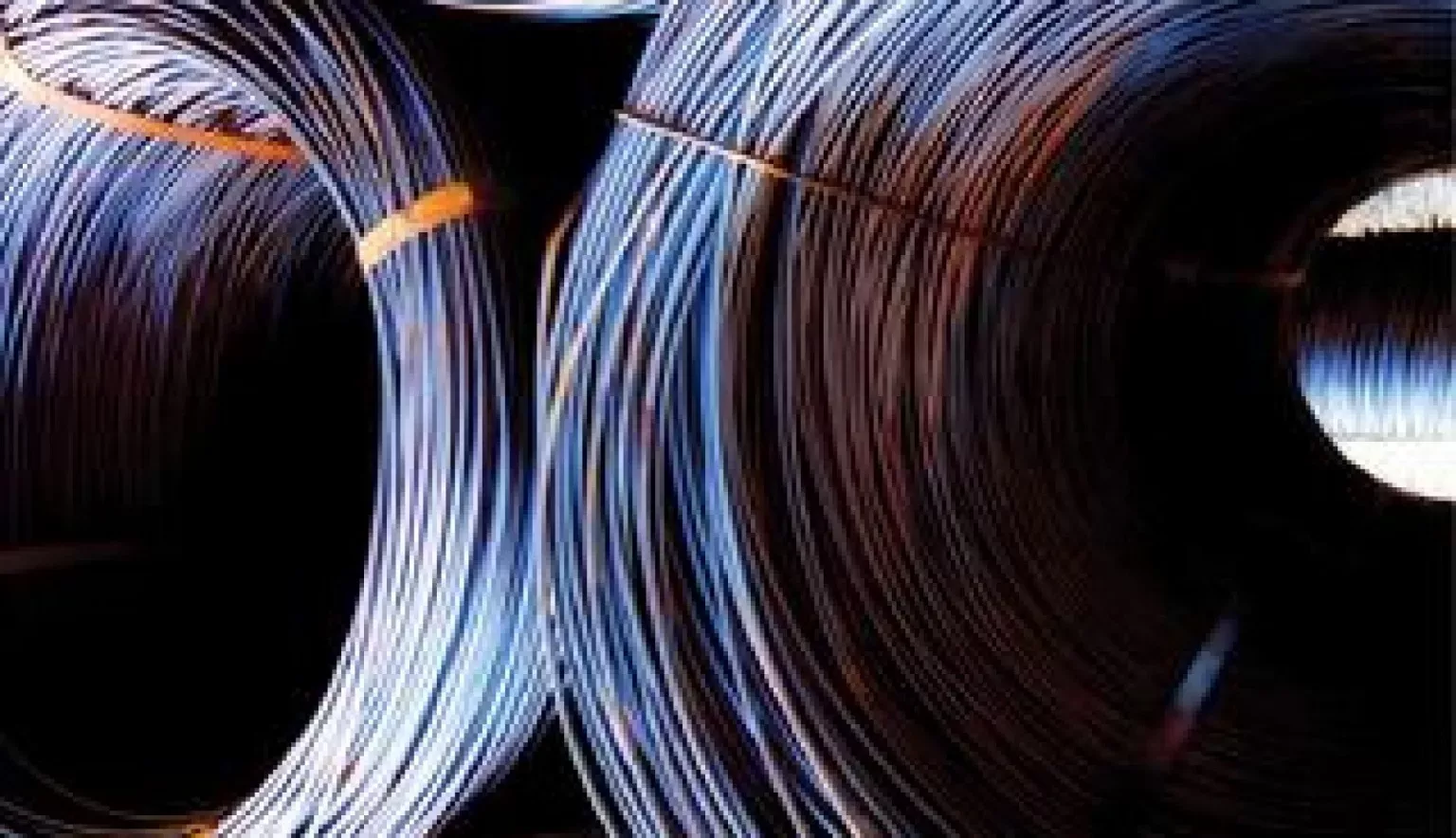

Reinforcing Mesh Solutions have become a nationally recognised industry leader of steel reinforcing and welded mesh fabric.

STEELY DETERMINATION

When it comes to building a successful business within the construction industry in South Africa, you need several key ingredients: dedication, industry knowledge, vision and most importantly, a high quality product that meets the needs of the market. Reinforcing & Mesh Solutions (RMS) fit that bill perfectly. Since their inception in 2002, with just one base of operations in Johannesburg, RMS have grown into a nationally recognised industry leader of steel reinforcing and welded mesh fabric.

André Nienaber, managing Director of RMS, has overseen the company’s steady growth since 2012 and the company now has 11 operation centres under his watchful eye across South Africa, including outlets in Johannesburg, Cape Town, Durban, Port Elizabeth, Lephalale and Rustenburg. With 39 years in the rebar industry, Nienaber certainly knows what it takes to make it in this highly competitive industry: “we always strive to ensure that we are constantly competitive in the market and to maximise this, we must be visible in as many cities across South Africa as we can. After all, our presence in a city gives prospective clients an opportunity to come and speak with us about projects and potential dealings,” Mr Nienaber cites.

TRAINING IS CRUCIAL

One of the bigger problems in the construction industry is a shortage of the skilled workers available. South Africa has one of the biggest construction markets in Southern Africa and yet it still relies on skilled workers from both neighbouring countries and foreign shores. In order to combat this shortage, RMS have implemented a training platform for workers that will teach and train them in all aspects of steel reinforcing and mesh solutions. “We train our new workers in-house, in the various capabilities of the company. Strong training is crucial to the future of the company. If we do not have a workforce capable of performing at the highest level, then we cannot be market leaders. Our training is mainly undertaken in Johannesburg, as it is one of the biggest facilities we have,” Nienaber continues: “We train, on average, 8 workers at a time in order to strike a balance between coaches and the students.”

A FLAT MARKET

The current economic climate has been felt particularly hard in Africa and even more so in the construction industry. With a severe lack of investment from the government or foreign companies, major construction projects have almost come to a standstill, while companies wait for the economy to pick up again. Nienaber has his own thoughts on the current lull in the workflow: “The government are not spending any money on civil and industrial projects and we are beginning to feel it across the sector. With upcoming elections there is a feeling that nothing will happen until a new government is in place or the incumbent is reconfirmed. However, there has been investment, albeit relatively small, from foreign companies and we are beginning to see small shoots of recovery, but it will be at least 1-2 years before we really see any difference in the market and the number of projects being tendered for.”

The second problem facing construction has been general worker strikes. South Africa has seen several big union and worker strikes in recent months which has had a huge impact on the time taken for a project to be completed. Labour unions are refusing to back down until demands for pay and working hours are met and this has led to a stalemate. Despite the disruption this has caused in the sector, RMS has managed to successfully continue work on two major projects: the Kusile Power Plant, which has been ongoing for the last two years and the Mall of Africa, which has been a more recent project, but both of which are high profile, multi-billion rand developments.

SUPPLY AND DEMAND

Construction projects require very specific materials and equipment on a project by project basis. RMS have a strong supplier list comprising of both local and international companies. “We mainly work with three major local suppliers, ArcelorMittal, Scaw Metals and SA Metal. We have been working alongside these companies for a number of years and our relationships with them are very good. We believe in transparent and open dialogue between us and our suppliers, so that if any query should arise we can quickly deal with it in a professional manner,” Nienaber explains, taking pride in this mutually beneficial approach to business. There are times however, when niche materials or a particular quantity of steel is required and RMS will have to import from abroad as Nienaber describes: “There are instances when we will need a large quantity of a specific material or steel compound, which our local suppliers do not have to hand, we will then source out a reputable supplier. We always ensure that the reputation of that supplier is the highest possible, as we ensure all our materials are the best standard available.”

5 YEAR PLAN

With RMS always looking towards the future with a clear vision, Nienaber is determined to ensure that the company is doing all it can to remain a market leader. “The company has been growing at a steady rate over the last two years and we have taken on more projects during that time. What we don’t want to do is stop expanding and continue to take on bigger projects and workloads. We have begun to look at potential expansion to the neighbouring countries in Africa; but that will bring with it new hurdles to overcome, the biggest being a different language. This is realistically a five year plan for us, as it will take careful consideration in research and project risk in order for us to really maximise the potential markets there.”